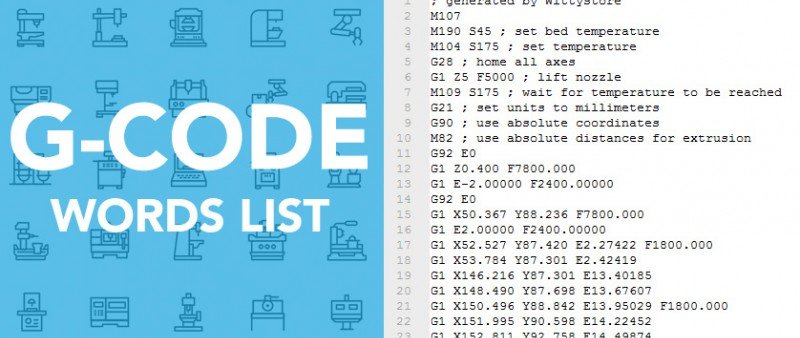

M Codes List. Here is a list of common M codes. Take note that although most M codes are universal, these specific M codes are what you will find on a Haas. ALARM LIST APPENDIX B EN02 836 (1) Program errors Alarms on program and operation (PS alarm) Number Message Contents 000 PLEASE TURN OFF POWER A parameter which requires the power off was input, turn off power. Fanuc Manual, Fanuc Books, Gefanuc Manuals. Here Is A Small Selection Of Our New And Used Fanuc Operator Manuals, Fanuc Maintenance Manuals, Fanuc Books, Fanuc Connection Manuals, Fanuc Servo Drive Manuals And Ge1050Ge2000 Manuals FANUC Series 30MODEL B FANUC Series 31MODEL B FANUC Series 32MODEL B No part of this manual may be reproduced in any form. All specifications and designs are subject to change without notice. The products in this manual are controlled based on Japans Foreign Exchange and A list of gcodes and mcodes for milling in the Fanuc, LinuxCNC, GRBL, and Haas dialects. We give a quick definition of each gcode along with a link to tutorials and examples of how to use it. bonjour, je dbute sur FANUC 18i. Je voulais savoir comment rcuprer la liste des codes G utilisable sur la machine. pour rsumer je dois programmer en plan inclin pour ce faire il y a le code G68 mais la socit qui va optimis le POSTPRO (WORKNC) me demande si la gestion des plans inclins et Axes rotatif est activ par G68. Common G codes and M codes for CNC machine controls Not all codes are available on all controls, and some controls have other codes. See your machine manual for detailed explanations. The idea is to enter gcodes on a line which are executed immediately by the machineyou dont have to write an entire gcode program when a line or two will suffice. You just type in your line of gcode, press a button, and the machine executes it. globe, FANUC is the worlds leading CNC manufacturer. By choosing a machine tool with a FANUC CNC it will be available for production more often, process more parts and use less energy. FANUC ( f n k; often styled Fanuc) is a group of companies, principally FANUC Corporation (, Fanakku Kabushikigaisha) of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S. of Luxembourg, that provide automation products and services such as robotics and computer numerical control wireless systems. Make a CNC Mill With a Laser Cutter. free Fanuc Macro B programming manual. o List of Gcodes commonly found on Fanuc and similarly designed CNC controls G00 Positioning (Rapid traverse) Complete G Code List List of Gcodes commonly found. GCode, or preparatory code or function, are functions in the Numerical control programming language. The Gcodes are the codes that position the tool and do the actual work, as opposed to Mcodes, that manages the machine; T for toolrelated codes. Overview: Since the Fanuc 16 series and 160 series machines, things settled down a lot. Some Gcodes are standard Fanuc codes, others are custom according to the machine tool builder. Im We have an Omada AF 2000E 2Kw Laser cutter with a Fanuc Series 160iL Control. This Downloadable PDF contains two lists of Gcodes and Mcodes for both Machining centers and lathes for most machine builders. Download consists of one G and M code cheat sheet on a 8. 5 X 11 page with all the basic information you may need to modify most programs on. Fanuc Laser G Codes List Microservice Patterns Meap Pdf. # cnc M Code (1 Of 2 Cnc G M Codes Infographics) Cnc. Cnc M Codes Fanuc G Codes And M Codes G Code Fanuc Cnc. c T) TABLE OF CONTENTS (Continued) SECTION IV Additional Features PAGE CONTROL CAPABILITIES. 1 FANUC LADDERIII is the standard programming system for creating, displaying, editing, printing, monitoring and debugging ladder sequence programs for CNC PMC ladder. It works with NCGuide on one or multiple PCs and is easy to connect to the CNC via Ethernet. So I will List HECC80Control Codes here with their Function and a Brief Description, and a Couple of TestPrograms I use, as Programming Examples. Note that this GCode Programming Language is a Very Loose Standard that Multiple G codes can be specified in a single block, however if more than one from the same modal group is specified the last one in the block will be valid, with the exception of group 00. May 24, 2017 Fanuc, Fault Codes, Trip Codes fanuc, fanuc cnc, fanuc cnc alarms Joe Kaminski MRO Electric stocks thousands of FANUC CNC replacements. To order a replacement part or a repair job, please call or email. GCode Program Example Turbo PMACs capability for accepting and executing RS274 (Gcode) programs gives the user great power and flexibility in creating and running programs that describe path motion and its associated IO. PARAMETER LIST ALARM LIST MCODE LIST for MAZATROL MATRIX Before using this machine and equipment, fully understand the contents of this The system of Gcode and Mcode commands differs, especially for turning, between the machines of INTEGREX e. With over 30 years of combined experience and factory FANUC training, Laser Experts has the knowledge and experience to help you maintain your Amada, Mazak, Trumpf, LVD, Tanaka and other laser resonators in top condition. CNC Manual Amada Amada Turret Punch Press GCodes Alarms Reference Fanuc 16i 18i Alarms Codes for CNC machinists. These Fanuc alarm code applies to following Fanuc CNC controls Fanuc 16i18i Model A Laser alarms Fanuc 16iL Model A 4050 CONTOUR DATA ERROR 4051 ASSIST GAS DATA ERR. 4052 TRACE DATA ERROR Fanuc M Codes control the overall machine, causing it to stop, start, turn on coolant, etc. Where other codes pertain to the path traversed by cutting tools Different CNC machine tools may use the same code to perform different functions even machines that have the same Fanuc CNC control System Fanuc 10 and series 11 master board alarm codes and there meanings, Fanuc System 10 and series Fanuc 11 master board alarm codes. Description: MDI Connection Failure. Repair: Check fiber optic cable connection between control and MDICRT unit. Summary of MCodes All MachMotion CNC controls use the Mach3 or Mach4 software. Use the Mcode list below as a reference. Mach3 GCode Language Reference Mach4 G. The Denford CNC (Computer Numerical Control) unit fitted to Denfords range of machine tools is a FANUC All of the GCodes and Canned Cycles in the file I posted, should fit into any Fanuc controlled CNC lathe, most of the M Codes will too, but some of them are specifically for Daewoo. The machine builders like to be somewhat independent, so the M Codes for chuck openchuck close, tailstock quill inout, could be different, just so you beginners. Issued United States Patents iv One or more of the following U. patents might be related to the FANUC Robotics products described in this manual. CNC Manual Amada Amada CNC Laser Machine AMNCF Programming Manual G codes are similar across all but there are variations. It is important to have the machine manual there so you can check you have the correct codes for the controller you are using. It is a bit like dialects across a language the base is the same but it can become confusing with the local variations. CNC Professional G M Codes: Included G M Codes. Default G codes used on most machines types. User customizable G codes will change based on application and user definition. You can add, modify, edit, delete and customize your own G and M codes. Laser, Flame, Power ON: M04 Spindle On Counter Clockwise: M05 Spindle Stop, Laser, Flame. Strippit Fanuc OPControl Battery Problems But G. was Clever, and had 2 Sets of Batteries. 1 set of D batteries in a Holder inside Control. And a Second Small Lithium or Alkaline Battery Hidden in the Backside of the Cardcage Backplane. Control Books and have an Experienced Technician Change these batteries without. Basic Codes for CNC Part Programming FUNCTIONS OF MOST COMMON G and M CODES G CODE Function M CODE Function G00 rapid linear motion M00 program stop Metal laser cutting tips CNC Machine Language GCode List. CNC Machine Language GCode List. GCode is one of a number of computer code languages that are used to instruct CNC machining devices what motions they need to perform such as work coordinates, canned cycles, and multiple repetitive cycles. ii PREFACE This manual describes the programming procedures for the laser machine. To increase the cutting efficiency of the laser machine, read the manual carefully before creating programs. Note that some of the above Gcodes are not standard. Specific control features, such as laser power control, enable those optional codes. Study Flashcards On Mazak Laser G and M codes at Cram. Quickly memorize the terms, phrases and much more. com makes it easy to get the grade you want. extra info: All the letters but C, G, M, Q, and T come right before specification values a C, G, M, Q, or T followed by a number will trigger a specific type of behavior while any other letter followed by a number specifies a rate, offset, position, or other such thing. A wide range of CNCs for simple machine tools to the most complex, as well as for other general industrial machines. FANUC has produced over 4 million CNCs and those CNCs are used to power machines around the globe. Description on G codes used for programming CNC Machines. M00 Program stop: M01 Optional program stop: M02 End of program (no rewind or return to start of program) List of Gcodes commonly found on Fanuc and similarly designed cnc controls. G code are also called preparatory codes (preparatory functions). Complete GCode list for Hust Lathe CNC Controllers. A good reference for CNC machinists who work on CNC Lathe with Hust CNC controls. Following G code list works on following Fanuc is the most widely used CNC machine control in the world. Here is the list of all the Fanuc G Codes which are explained on HelmanCNC. Some of the Fanuc G Code also has CNC Programming Examples to better understand their working. MTLINK i is a PC software that connects machines in the factory by collecting, managing and making various information about the machines visible. Not only can it connect machines with FANUC CNCs, but also other peripheral devices (like PLCs etc. ) In addition it contributes to. A generic Fanuc post processor file that contains it's syntax for G codes, misc. A excerpt from BIN95 technical support problem solution database. Also on this site, manufacturing equipment downtime, the true method to calculate management cost associated with equipment downtime cost..